Description

Crystallization Tank

What is Crystallization Tank

Crystallization(also known as Crystallisation) is the process where a solid formed into a structure of the crystal. The commonly seen methods of crystallization are by precipitating or freezing from a solution. Factors that will influence the property of crystallization result include temperature, air pressure, distilling time and others.

The crystallization happens in nucleation and crystal growth phases. The former refers to the appearance of crystalline; the latter means the increase of crystal particle size until there is a clear crystal subject.

Joysun industrial stainless steel crystallization tank is the equipment to do crystallize, widely used in pharmaceutical, dairy, food, chemical, beverage, and other industries, cooling and freezing crystallization of finished products.

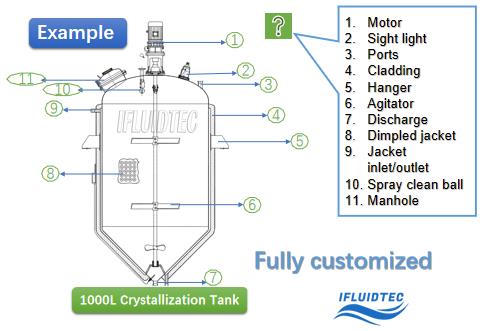

Crystallization Equipment Design Diagram

How to Buy Crystallization Tank?

For beginners who don’t know the structure and parts on crystallization vessels, we strongly suggest you check out the below aspects. (the below sketch will give a general idea of crystallization reactor making; the variants can be much)

1. Motor: a driving system on the vessel to make agitators rotate. It is easy to understand that more viscous liquid is, bigger motor power should be. And the liquid fluidity will influence the form of the agitator. The speed of agitator also differ. The voltage system should also be clear as to use in different countries.

2. Sight light: an Led light will be installed on top of the tank which helps operators to see through inside.

3. Ports/nozzles: several sanitary ports on the tank for different purposes such as for water inlet, material inlet, vent, gauge installation and etc., how many nozzles on the tank are upon the actual usage.

4. Cladding: refer to the most outside layer of the tank. Normally the crystallization reactor has three layers of inside layer, jacket, and cladding.

5. Hanger: especially for a tank that will be placed on a platform; sometimes a tank with standing feet can also have this upon the specific requirement.

6. Agitator: can be installed from top-down and bottom-up, depends on material and crystallizing methods.

7. Discharge: as easy as the word means. We can install suitable valves here to unload specific material. Or leave it for buyers.

8. Jacket: the heating layer of reactors which has several designs like coil jacket, dimpled jacket, steam jacket, hot water jacket or cooling jacket, or even double jackets.

9. Jacket inlet/outlet: either liquid or gas can entry jacket via those ports.

10. Spray clean ball: installed as required.

11. Manhole: can be the regular ambient type or high-pressure type.

We manufacturing of such a tank strictly follows both parties’ confirmed drawings. We have secure QA and QC.

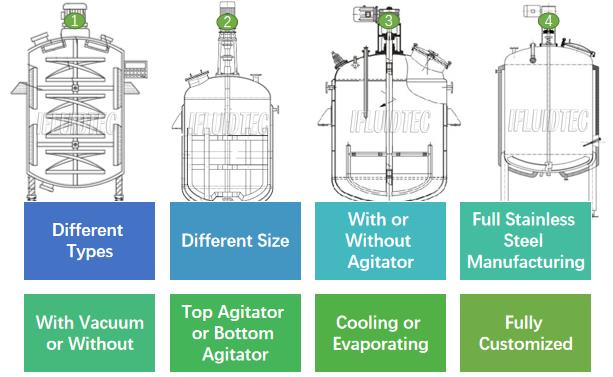

Types of Crystallization Tank

We can customize various types of crystallizer according to the user’s need upon different material and crystallizing processes. A wide range of options is available to buyers including the size/volume of crystallizer, the agitator forms, and its installation place; manufacturing material 304 or 316L; 316L material is more costly than 304 but is better at rust-proof. We can have a cooling way to do the crystal or evaporation way, there is no absolute clear distinction between the two methods, usually a hybrid combination of two.

Crystallization Equipment Characteristics

• The crystallizing tank has various specifications ranging from 600L to 20,000L, which can be designed and manufactured according to the actual needs of customers.

• The crystallization tank uses a mechanical seal of the special hygienic degree to ensure that the material is not contaminated.

• The crystallizer adopts VFD regulation, the rotation speed of the stirring can be adjusted in a wide range from low speed to full driving rotating.

Crystallization Vessel Technical Parameter

| Item | Model | JJG-600 | JJG-1000 | JJG-2000 | JJG-3000 | JJG-4000 | JJG-5000 |

| Volume(L) | 600 | 1000 | 2000 | 3000 | 4000 | 5000 | |

| Tank | DIA(mm) | Φ900 | Φ1100 | Φ1300 | Φ1600 | Φ1700 | Φ1800 |

| Height(mm) | 900 | 1000 | 1500 | 1500 | 1800 | 1800 | |

| Stir | Power(KW) | 1.1 | 2.2 | 2.2 | 3 | 3 | 4 |

| speed(r/min) | 0-100, customization is available | ||||||

| Item | Model | JJG-6000 | JJG-8000 | JJG-10000 | JJG-12000 | JJG-15000 | JJG-20000 |

| Volume(L) | 6000 | 8000 | 10000 | 12000 | 15000 | 20000 | |

| Tank | DIA(mm) | Φ1900 | Φ2000 | Φ2200 | Φ2400 | Φ2600 | Φ2800 |

| Height(mm) | 2000 | 2200 | 2400 | 2500 | 2700 | 3000 | |

| Stir | Power(KW) | 4 | 5.5 | 7.5 | 7.5 | 11 | 11 |

| speed(r/min) | 0-100, customization is available |

Reviews

There are no reviews yet.