Description

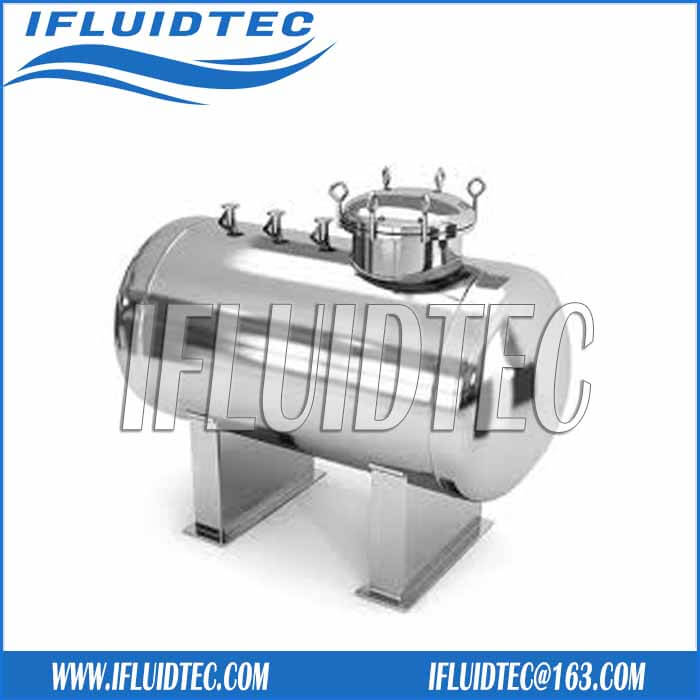

100-20000Litre Stainless Steel Storage Tank Pressure Vessel

Stainless Steel Storage Tank Application

Stainless Steel Storage Tank can always find its way in different using areas as long as there are needs for keeping the material either liquid, powder, paste, raw material, half-finished product or finished products. Upon the storage condition of different materials, the design of the stainless steel tank is also of a large variety. To name a few and to show some examples, we’d like to make buyers understand how to put the right order and good purchase.

Stainless Steel Storage Container design and manufacturing standard

GB150-2011 the national pressure vessel standard of China.

NB/T 47003.1-2009 steel welded atmospheric pressure vessel standard of China.

Strictly meet GMP certificate requirements

Outside of China, Extra certificates such as ASME, CE are available upon request.

Material to Make Steel Pressure Vessels

Inner liner contacting material: 304/316L optional, overall material is 304

Insulation: PU or rock wool (to insulate inside/outside heat transfer)

Surface Finish

Inside tank/vessel/reactor/kettle is mirror well-polished to 0.3μm.

Outside tank/vessel/reactor/kettle can be mirror polish, matte polish.

The inside tank furnish is very crucial for pharmaceutical use tanks; there should be no dead angle or small holes that residue can stay in. We are very careful in steel tank fabrication.

How to Check Each Parameter on the Tanks

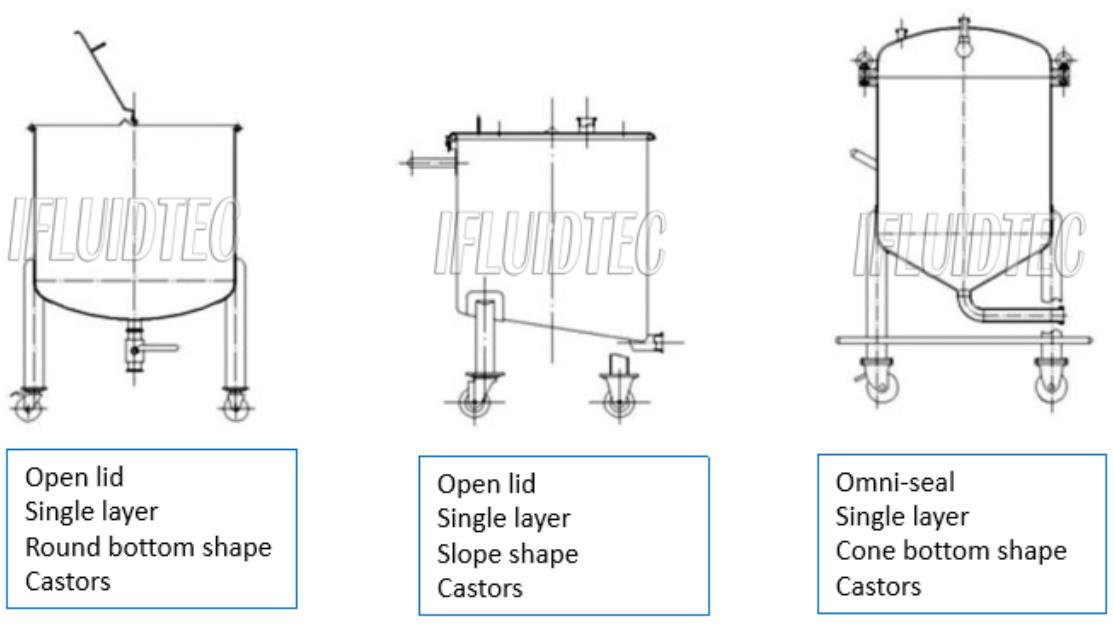

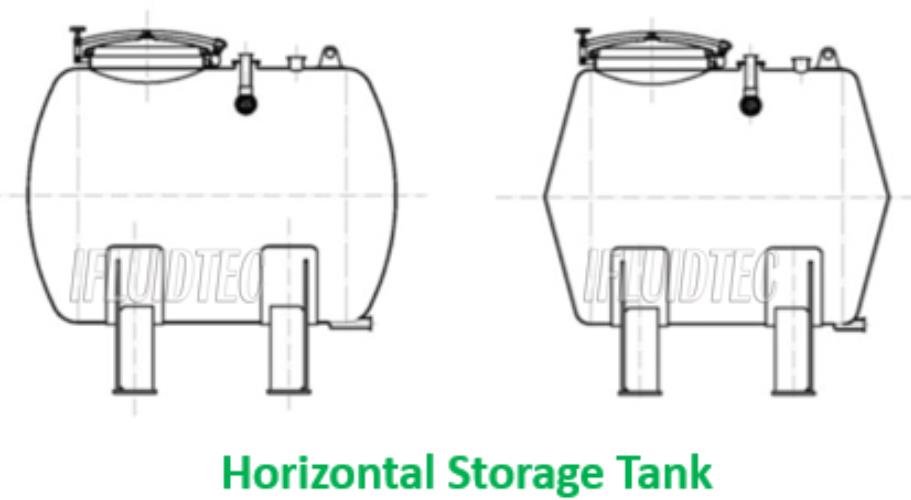

The below sketch is just a few of our drawings.

1# Tank Size

The tank can be as small as 50L and as big up to 20,000Litre according to the buyer’s requirement.

2# Tank Lid

The lid/cover that is welded together with the tank body is the hermetically sealed type. This kind of design tank can work under vacuum and under positive pressure. (about how much psi/bar/mPa pressure is usually upon buyer’s usage needs); A steel tank with an open or removable lid is easier to use than welding type. We will use a flange connection or quick open tri-clamp on the tanks. Also higher pressure for the tank, thicker stainless steel plates will be used and more strong welding is adopted. As a professional pressure vessel manufacturer, we clearly know how to design and fabricate.

A pressure conversion table for reference.

| bar | psi | kPa | MPa | bar | psi | kPa | MPa | bar | psi | kPa | MPa |

| 1 | 14.5 | 100 | 0.1 | 10 | 145 | 1,000 | 1 | 100 | 1,450 | 10,000 | 10 |

| 2 | 29.0 | 200 | 0.2 | 20 | 290 | 2,000 | 2 | 200 | 2,900 | 20,000 | 20 |

| 3 | 43.5 | 300 | 0.3 | 30 | 435 | 3,000 | 3 | 300 | 4,350 | 30,000 | 30 |

| 4 | 58.0 | 400 | 0.4 | 40 | 580 | 4,000 | 4 | 400 | 5,800 | 40,000 | 40 |

| 5 | 72.5 | 500 | 0.5 | 50 | 725 | 5,000 | 5 | 500 | 7,250 | 50,000 | 50 |

| 6 | 87.0 | 600 | 0.6 | 60 | 870 | 6,000 | 6 | 600 | 8,700 | 60,000 | 60 |

| 7 | 101.5 | 700 | 0.7 | 70 | 1,015 | 7,000 | 7 | 700 | 10,150 | 70,000 | 70 |

| 8 | 116.0 | 800 | 0.8 | 80 | 1,160 | 8,000 | 8 | 800 | 11,600 | 80,000 | 80 |

| 9 | 130.5 | 900 | 0.9 | 90 | 1,305 | 9,000 | 9 | 900 | 13,050 | 90,000 | 90 |

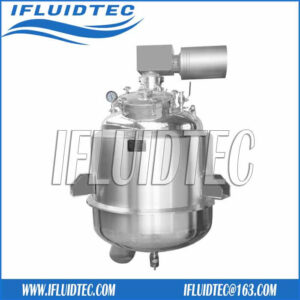

3# Fittings on top of tank

To make the tank suitable for usage, there are several nozzles/nuzzles/ports/openings on top of the tank; those nozzles can work as the inlet for feeding material or vent for air or installing places for gauges like temperature and pressure. The buyer should consider how many nozzles they need on the tank and the function of each one. Other fittings like air breather, filter, thermometer, sight glass, manhole, handhole, CIP cleaning ball, and valves, to name a few.

4# Insulation layer and jacket for tanks

The buyer can choose a single layer stainless steel tank if the material is kept under ambient temperature. For raw material that needs to store at a certain temperature, then an insulation layer or even a heating/cooling jacket is necessary. We can put an electric heater in the jacket where the media in the jacket can be heated up. The insulation layer stuffed with PU is good for keep cooling conditions while rock wood-filled insulation layer is best at heat preservation.

5# Material Discharge Port

Considering the user operation and material easy discharge, we usually fabricate the discharge port at the lowest part of the tank, at the middle center of the bottom or at the side bottom. It can be chosen upon the user’s preference. This port is with a close/open valve to control material like ball valve, butterfly valve, diaphragm valve.

Reviews

There are no reviews yet.