Description

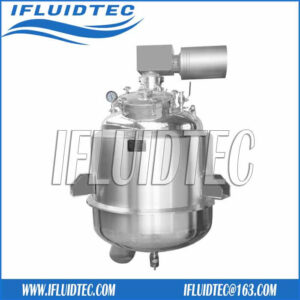

Top Entry High Shear Mixer for Batch Production

High Speed Mixer Application

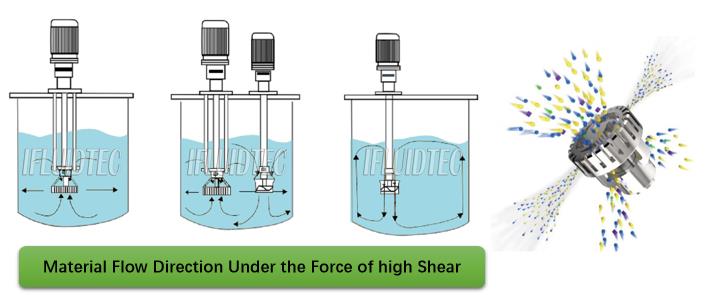

We combine the electro-hydraulic lifter together with top entry high shear mixer so that it will be very easy to use. The shear head goes up and down by just press the ‘UP/DOWN’button on the operation panel. The user can control the depth of the mixing head that drops into a tank. This design is also convenient to clean the mixing equipment.

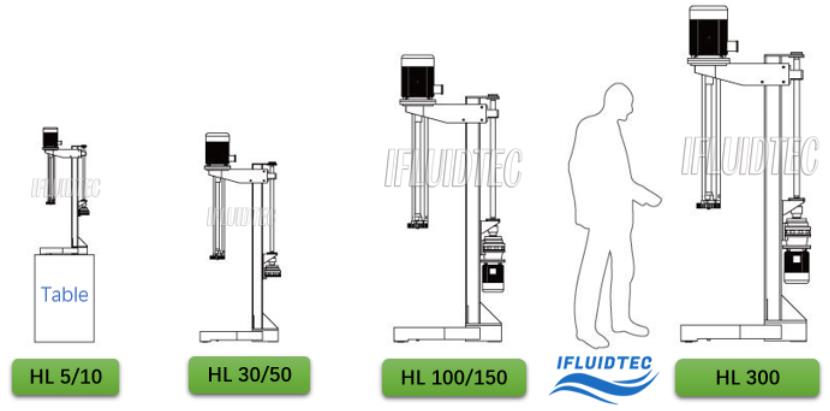

Available Sizes

Technical Parameter or Custom Made

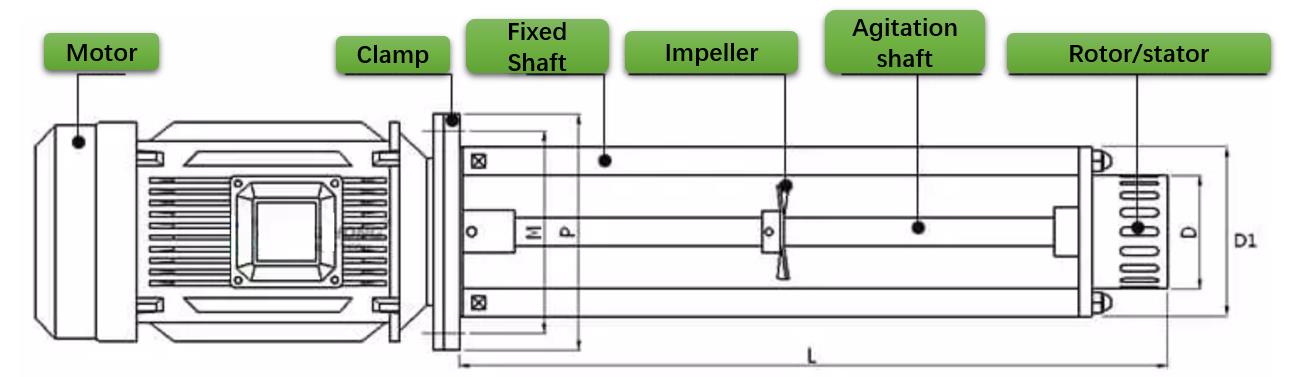

Rotor and Stator assemble rotates at high speed around 2200rpm-3600rpm creating a strong force that can inhale material into the center of the shearing part and then jet out in radial patterns. This continuous circulation of inhaling and jet will crush down material particles into very small sizes to 200-2000nm(the tangential velocity can be 15m/s-40m/s). Materials after jet out will hit the tank walls in a round direction, goes down to the bottom of the tank, then be sucked into the homogenizer center again. 316L austenitic stainless steel is used, more acid resistant, more alkalis resistant and more high temperature resistant.

Top Entry Homogenizer Parameter

| Model | Power/kW | Rotation speed RPM | Capacity(L) |

| HST-80 | 1.5 | 2900 | 20-100 |

| HST-100 | 2.2 | 50-300 | |

| HST-120 | 4 | 100-500 | |

| HST-140 | 5.5 | 200-800 | |

| 7.5 | |||

| HST-160 | 11 | 300-1000 | |

| 15 | |||

| HST-180 | 18.5 | 500-1500 | |

| HST-200 | 22 | 1450 | 800-2000 |

| HST-220 | 30 | 1000-3000 | |

| HST-240 | 37 | 1500-5000 | |

| HST-270 | 55 | 2000-8000 | |

| HST-290 | 75 | 3000-10000 |

Tags: Vacuum Emulsifying Mixer, vacuum homogenizer, vacuum emulsifier, vacuum emulsifying machine, high shear mixer, high shear dispersing emulsifier, high speed emulsifier, high speed homogeniser

Reviews

There are no reviews yet.