Description

Sanitary Liquid Filter of High Capacity

JTBF Sanitary Liquid Filter of High Capacity, a bag filter used with filter bags, is used for coarse filtration and pre-filtration. It has large processing flow, long service life and easy operation. It is a filter with obvious advantages.

JTGDS Sanitary Liquid Filter of Large Capacity comes standard with No. 01 filter bag (Ø180*430) or No. 02 filter bag (Ø180*810), the standard mode is 2 bags to 12 bags, and the maximum production of customized bags is 24 bags, which can basically meet the requirements of various flow rates.

Operation Conditions

Max. Operation Pressure: 1.0Mpa.

Max. Temperature: 150℃.

Contact Parts Material (shell and valve): 304 or 316L as optional.

Sealing Ring& Gasket: EPDM, PTFE, VITON, SILICA

Surface Finish: 1# mechanical polishing; 2# electrolytic polishing; 3# sand blasting, can choose

Polishing: ≤0.6μm inside and basket, ≤0.8μm outside.

Connection of Shell: Flange.

Connection of In-outlet: Flange,Tri-clamp,Thread.

Connection of instruments (option): Female thread.

Connection of valves (option): Male thread.

Application

Bag filters are mainly used in the purification process of various liquids in the following industries:

- Food and beverage

- Bioengineering and medicine

- Petrochemical and chemical industry

- Car manufacturing

- Oil, natural gas

- Electronics, electroplating

- Coatings, paints, inks

- Textile, printing and dyeing, papermaking…

The filter can also be used in nuclear power and thermal power and waste liquid filtration, photographic film production process liquid filtration, daily chemical liquid and gas purification, and various coolant filtration processes in the mechanical processing and refrigeration industries.

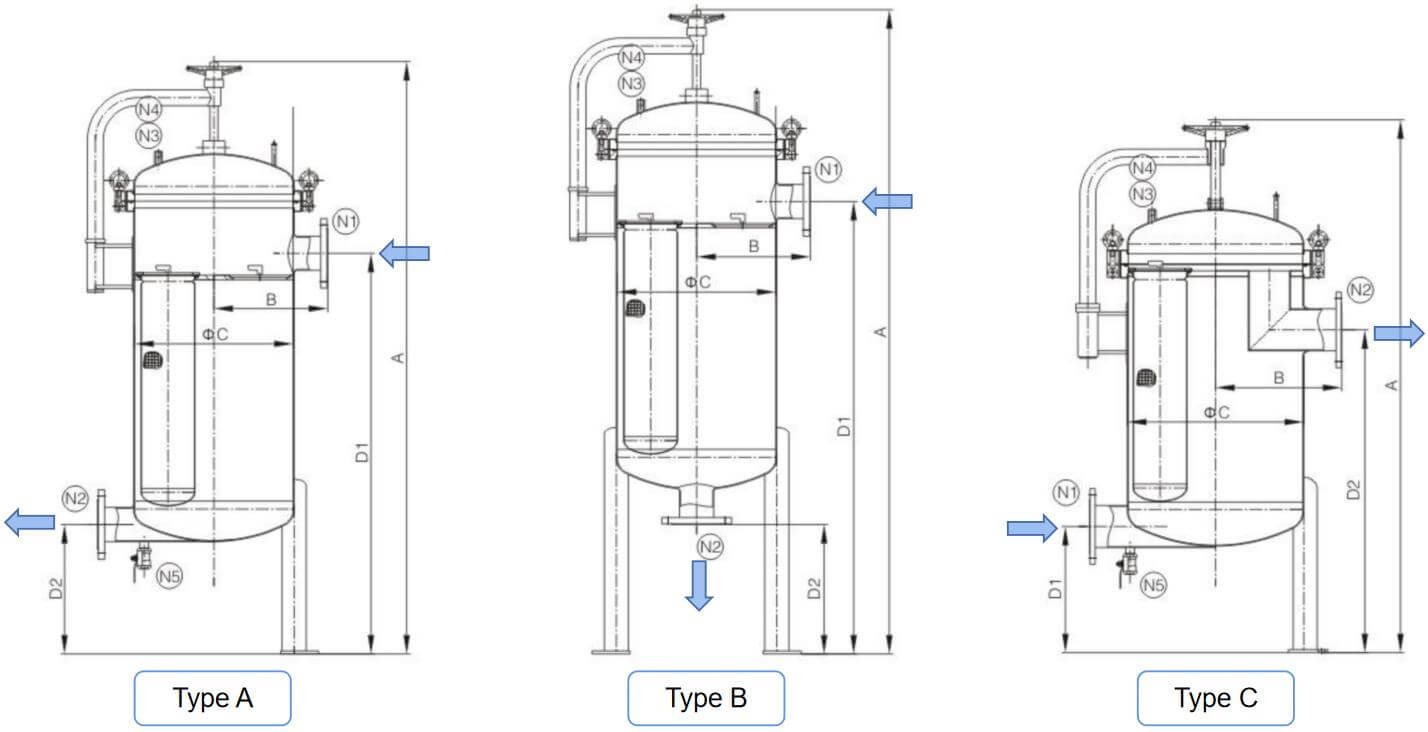

Sanitary Liquid Filter of Large Capacity Structure

Dimension

| Qty. of Bag Filter | In-outlet Tpype | Diameter of In-outlet | Height(A) | Length(B) | Diameter of Shell(C) | Height(D1) | Height(D2) |

| 2 | Type B | 4" | 1880 | 300 | Ø400 | 1330 | 300 |

| 2 | Type C | 4" | 1530 | 300 | Ø400 | 950 | 300 |

| 4 | Type B | 4" | 2030 | 360 | Ø500 | 1425 | 400 |

| 4 | Type C | 4" | 1600 | 400 | Ø550 | 975 | 350 |

| 6 | Type B | 5" | 2130 | 440 | Ø650 | 400 | 1480 |

| 6 | Type C | 5" | 1700 | 450 | Ø650 | 400 | 1000 |

| The above table is the standard filter data equipped with No. 02 filter bag, which can be customized according to customer requirements. |

Reviews

There are no reviews yet.