Description

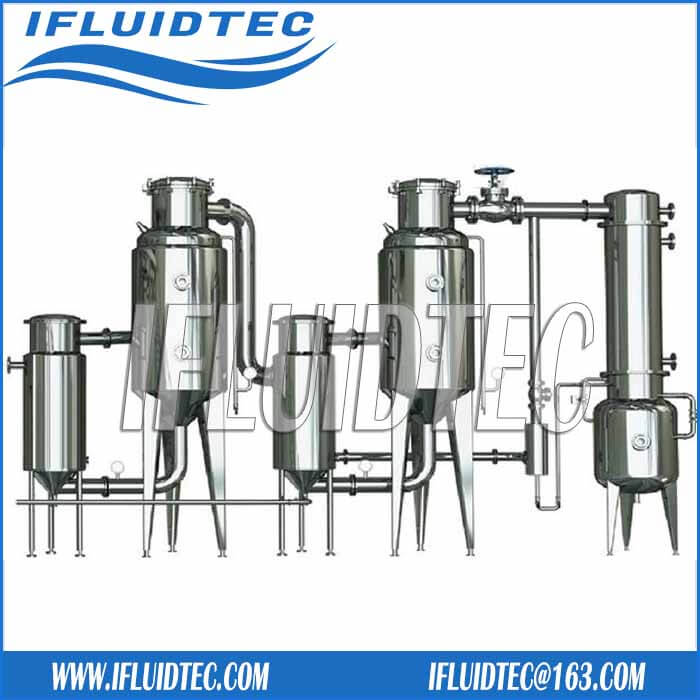

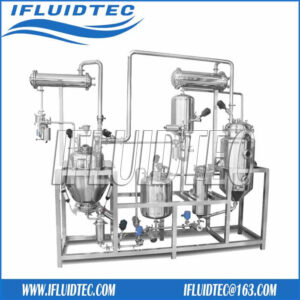

Single Double Triple Effect Evaporator

Stainless Steel Evaporator

Evaporation is a process in which a type of solvent in the solution is vaporized and removed by heating, thereby increasing the concentration of the solution and promoting the solute precipitation. The necessary conditions for the evaporation process to be continued are the constant supply of thermal energy to the solution and the continuous removal of the solvent vapors produced. The boiling point of the solution is increasing along with the rising of its concentration. The steam generated from the evaporator that will be used for heating the secondary evaporator is referred to as secondary steam.

Single-Effect Evaporator

A set of a single evaporation device, it will not re-use the steam generated from its first-time evaporation. The steam will be drained or recycled directly, not going back to the evaporator device to be used as a secondary heating source. The characteristic is that the secondary steam generated is not used to further evaporate the material. For single-effect evaporation, under sure working conditions, it is usually necessary to calculate the amount of water evaporation, heating steam consumption, and heat transfer area of the evaporator.

Multi-Effect Evaporation

Double, triple or quadruple effect evaporators belong to this category. Such evaporators are designed to save steam. If one set includes two evaporators is called double effect evaporator; if three evaporation tanks in a set are called triple effect; the rest can be done in the same manner.

Usually, the first effect is operated at a certain pressure, and the pressure of the second effect is lower, which results in a suitable temperature difference and allows the liquid in the second effect evaporator to evaporate. In the same way, after the temperature in multiple evaporators has passed for a certain period of time, the temperature difference and pressure difference are adjusted automatically to reach stability, so that the steam can be continuously carried out.

Due to the repeated use of thermal energy for many times, the amount of thermal energy consumption is significantly reduced, so multi-effect evaporation is conducive to a large number of continuous production of stream extracts or extracts and concentrated Chinese herbal medicine preparations. In addition, multi-effect evaporation can also be used to prepare water for injection(WFI).

Stainless Steel Evaporation Tank Characteristics

1. The inlet of the evaporator is designed as a diversion channel so that the vapor-liquid mixture enters the evaporator completely tangentially. The liquid fall down alongside the inner wall of the evaporator, during the process, the vapor is separated from the liquid and be taken out of the evaporator. The tangential angle loading way of material is better than the conventional design where the liquid can avoid splash right onto the tank inner wall, make sure all liquid comes down evenly.

2. Our evaporator design is relatively lower than others which ease the inspection of the operator by just standing on the floor, no need ladder or platform. And operators can check several evaporators at the same time.

3. The manhole of the evaporator is designed at the lower part, the lid is using glass material, which has excellent observation vision and easy cleaning of the evaporator.

Single-Effect Evaporator Model& Parameter

| Model | DEVA-500 | DEVA-1000 | DEVA-1500 | DEVA-2000 |

| Evaporation Capacity(kg/h) | 500 | 1000 | 1500 | 2000 |

| Recycled Liquid(%) | 70~85 | |||

| vapor pressure(MPa) | 0.25 | |||

| Vacuum(MPa) | 0.02~0.08 | |||

| Heating/cooling(m2) | 10/30 | 20/60 | 30/90 | 40/120 |

| Air consumption(kg/h) | 350 | 700 | 1050 | 1550 |

| Cooling water(T/h) | 25 | 45 | 70 | 90 |

| Air suction(m3/h) | 110 | 230 | 340 | 530 |

| Weight(kg) | 1450 | 2000 | 3000 | 3700 |

Double-Effect Evaporator Model& Parameter

| Model | SJN-2-1000 | SJN-2-1500 | SJN-2-2000 | SJN-2-3000 | |

| Evaporation Capacity(kg/h) | 1000 | 1500 | 2000 | 3000 | |

| Vapor Pressure(MPa) | <0.25 | ||||

| Air Consumption(kg/h) | ≤600 | ≤900 | ≤1250 | ≤1650 | |

| Condense rate(MPa) | ≤1.25 | ||||

| Cooling water(T/h) | 40 | 60 | 80 | 120 | |

| Heating/cooling area(m2) | 15/30 | 20/45 | 30/65 | 40/90 | |

| Vaporing temp(℃) | One effect | 80~90 | |||

| Secondary effect | 55~70 | ||||

| Vacuum(MPa) | One effect | 0.02~0.04 | |||

| Secondary effect | 0.05~0.06 | ||||

| Air suction(m3/h) | 300 | 300 | 550 | 850 | |

| Dimension(L*W*H)(m) | 5*1.6*3.5 | 6*1.6*3.7 | 7.2*1.7*4.3 | 8.1*1.8*4.9 | |

| Weight(kg) | 1900 | 2600 | 3300 | 4000 |

Triple-Effect Evaporator Model& Parameter

| Model | SJN-3-1000 | SJN-3-1500 | SJN-3-2000 | SJN-3-5000 | |

| Evaporation Capacity(kg/h) | 1000 | 1500 | 2000 | 5000 | |

| Vapor Pressure(MPa) | 0.25 | ||||

| Air Consumption(kg/h) | 350 | 600 | 800 | 1800 | |

| Condense rate(MPa) | 1.25 | ||||

| Cooling water(T/h) | 30 | 40 | 50 | 140 | |

| Heating/cooling area(m2) | 15/30 | 20/45 | 30/65 | 40/90 | |

| Vaporing temp(℃) | One effect | 85~95 | |||

| Second effect | 70~80 | ||||

| Third effect | 55~65 | ||||

| Vacuum(MPa) | One effect | -0.04 | |||

| Second effect | -0.06 | ||||

| Third effect | -0.08 | ||||

| Air suction(m3/h) | 300 | 450 | 550 | 1600 | |

| Dimension(L*W*H)(m) | 6.5*1.5 | 7*1.7 | 7.5*2*4 | 8*2*4.5 | |

| Weight(kg) | 2200 | 3000 | 3750 | 5300 |

Reviews

There are no reviews yet.