Description

CBD Oil Extraction Machine(Cannabis Extraction Machine)

Cannabis CBD Oil Extract and Process Machine

With the discovery of the medicinal value of cannabis and the rapid development of the cannabis medicinal industry, more and more manufacturers have transitioned from the initial R&D stage to medium and large-scale production. Consumer’s understanding of marijuana is also deepening. Here we will recommend some cannabis oil extraction and processing equipment, models ranging from experimental machines to large-scale production.

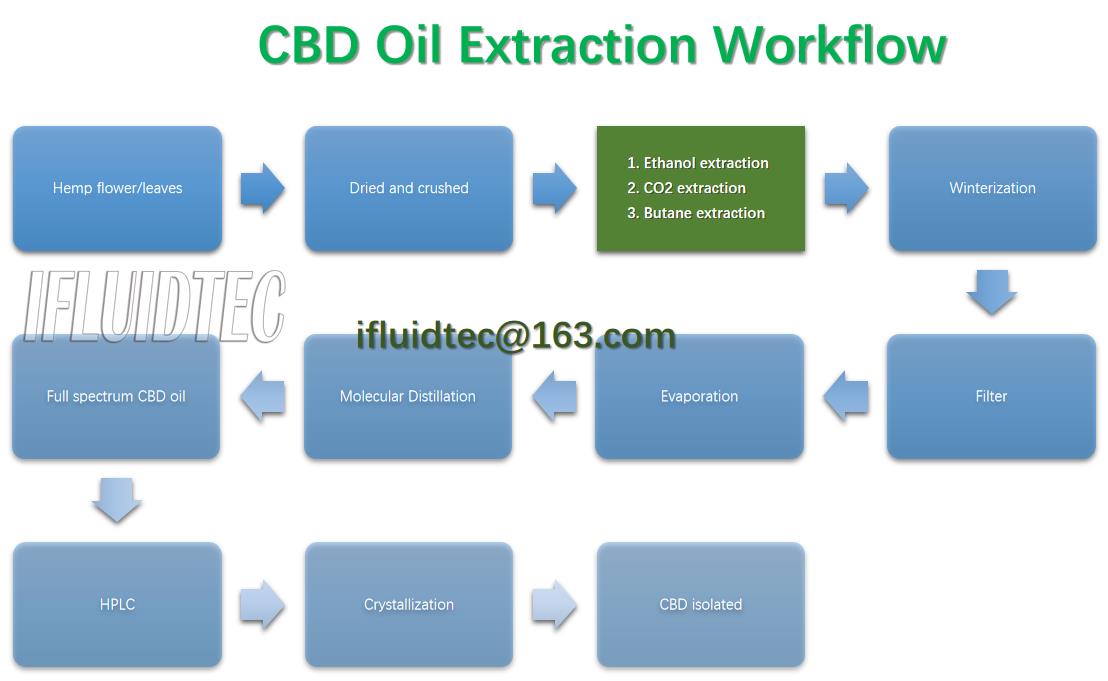

Cannabis whole treatment process can be divided into many steps, including plant raw material cultivation and picking; dry material treatment; selection and crushing treatment; hemp crude oil extraction; impurity removal; refining; separation and drying and etc.,

CBD extraction refers to the process to extract cannabidiol from hemp biomass. It matters to choose a professional, reliable CBD extraction machine manufacturer when trying to get CBD distillate, isolate or full-spectrum.

There are currently three types of extraction methods to extract and process cannabis plants (flowers and leaves).

1. Supercritical Carbon Dioxide Extraction(CO2 extractor).

The C02 CBD extractor applies high pressurized carbon dioxide (C02) and very low temperatures to extract natural cannabinoids, terpenes, and oils from the hemp plant. It is clean, fast and will not leave toxic residues in the finished CBD crude oil.

2. Subcritical Butane Extraction(BHO extractor).

Butane extractor uses lower pressure than co2 extractor, while a smaller output too. The pros of subcritical extraction are that the finished product retains more natural terpenes, oils, and phytochemicals from the hemp. It is chosen by many users to process cannabis, but it actually used more widely in other purposes of botanical extractions.

3. Alcohol Extraction under low temperature

The above three extraction methods have their own advantages and disadvantages. Here we will introduce readers with the low-temperature alcohol extract machine applied in the cannabis industry.

Ethanol CBD extraction Machine

The ethanol/alcohol extraction system is more favored by medium to mass production of the CBD hemp extraction companies. Ethanol extraction by the meaning is using alcohol as a solvent which has been already widely seen in many other plant oil extractions. Alcohol by itself is low risk and can be recycled after the extraction; the residue can be also controlled within the FDA requirement of <0.5%. It is currently a relatively mature, safe and economic extraction way for CBD oil. The extracting temperature can be room-temperature/ambient or super cool temperature(-40℃,-80℃ or even lower). By controlling temperature, the company can get different results. Now manufacturers are trying to get as lower temperature as possible to refine CBD isolate and distillate because super cool can get rid of more wax and pigment from crude oil.

Then which method to choose? This is something related to budget and goals. Different levels of extraction scale and different goals for the end products will affect the buyer’s choice. The market, need and cost will determine the decision.

How does Ethanol Extraction Work in Big Batch?

1. Soaking Tank: dried and crushed hemp strains will be firstly soaked into chilled alcohol, let the solvent penetrate particles gradually and can speed up extraction speed and make extraction more efficient. To prepare supercooled alcohol, we will need an industrial ultra low-temperature freezer.

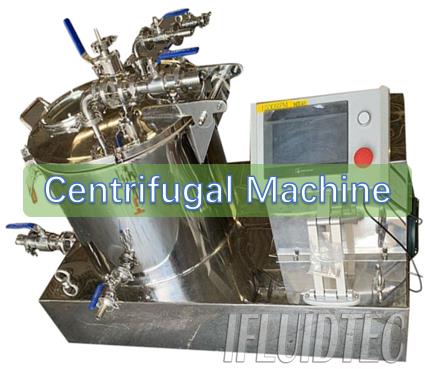

2. Ethanol Extractor: after enough time soaking, materials go to alcohol extractor for extraction. with time, temperature and pressure controlled, biomass is under mixed, the extracted liquid flows to be filtered where we will use specially made pipe filter and centrifugal separators(inline production line type).

3. Concentration and Evaporation Process: a set of vacuum and concentration units will be used to accumulate crude oil.

4. Short-Path Molecular Distiller: to purify crude oil, get CBD distillate.

5. HPLC: High-Performance Liquid Chromatography to separate THC and CBD.

6. Crystallization: to get CBD isolated.

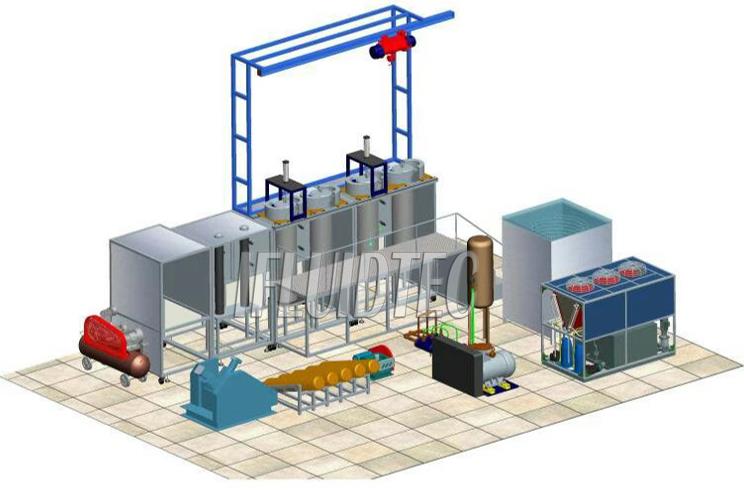

Devices Needed in the Hemp Extraction Process

What We Can Provide?

Welcome to contact us for cannabis projects, we provide the before-sales inquiry and consulting; sample testing; factory inspection; One we double confirmed the project upon user’s demand such as production scale, market goals, process technology, the engineer will design a production line for budgeting. The design should be both parties’ confirmation to make sure the implementation of all steps. Then factory manufacturing will be carried out strictly according to drawing and well tested before dispatch. During the equipment commissioning, our engineer will provide guidance on the site and carry out various tests with respect to all performances of the equipment. Approval will be received from users.

Reviews

There are no reviews yet.